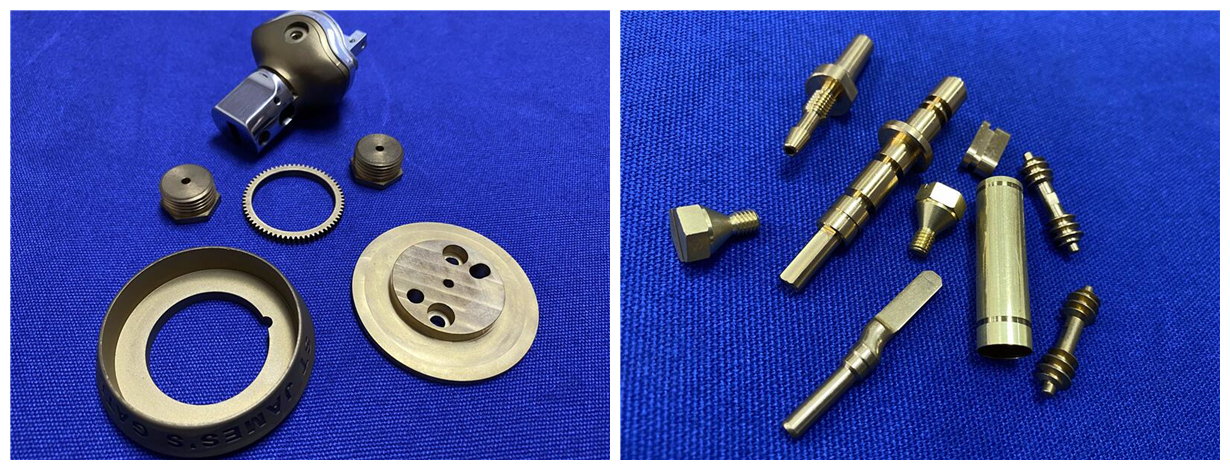

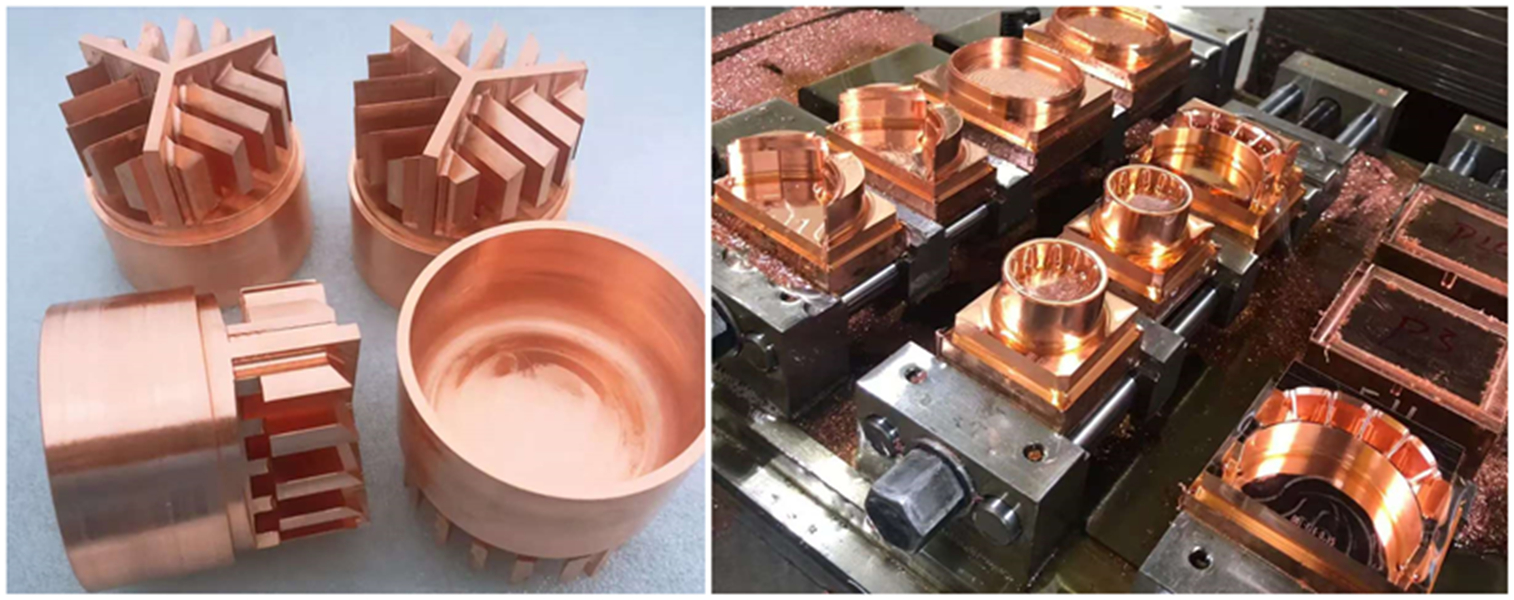

We offer precision brass CNC machining services, including CNC milling, turning, grinding, wire-cutting, and EDM. As a trusted custom brass CNC machining supplier in China, LJZ CNC deliver high-quality brass parts with fast worldwide shipping. Copper or brass exhibits excellent conductivity, ductility, corrosion resistance, wear resistance, and other unique properties, which make brass or copper machining parts widely used in power, electronics, energy, machinery, and other fields. We are equipped with complete and professional technologies for copper and brass CNC machining, we stand out as reliable china brass machining suppliers dedicated to crafting premium china brass machining parts for global clients.

LJZ CNC is one of the professional brass machining companies and copper machining suppliers. Our custom machining technology will be your steady and firm partner for brass and copper machining. Get an instant quote for your custom brass CNC parts — upload your drawing today!

Copper and brass are very active metals and are easily oxidized. As professional china brass machining suppliers, our commonly used machining surface finish treatments for CNC China brass machining parts and copper machined parts are passivation and electroplating.

Passivation has the effect of preventing oxidation and corrosion, and can effectively protect the surface of copper and brass products.

Electroplating can enhance the corrosion resistance of copper and improve conductivity and heat resistance, further elevating the performance of china brass machining parts for high-end applications supplied by leading china brass machining suppliers.

Our full-service workflow includes not only machining but also surface finish services such as plating, passivation, and polishing to meet high-end appearance or conductivity requirements.

For high-precision turning of custom components, you can also check our CNC turning services that support complex brass parts.

Our brass CNC machining capabilities include tolerance to ±0.01 mm, turning, milling, and finishing processes like passivation and electroplating—ideal for precision brass components. At LJZ CNC, we deliver durable and cost-effective CNC brass parts that set the standard for China Brass Machining Suppliers. LJZ brass screw machine parts are made to meet your specifications and requirements! You will get the most advantages of our brass and copper CNC machining service:

Latest CNC technologies enable us to machine different brass or copper parts. Familiarity with different materials' characteristics helps us to offer you valuable suggestions for your project.

Custom machining, single prototype machining, or a large batch of brass screw machine parts with in-time worldwide delivery.

A spectrometer detects raw materials to ensure their authenticity and safety, laying a solid foundation for high-quality china brass machining output.

Look for high-quality copper or brass parts. Start with LJZ CNC for a free quote now!

CuZn5 brass has good cold and hot working properties, suitable for extrusion, barbing, stamping, drawing, forging, and other processing methods, easy to weld and tin. Generally used in detonators, shells, enamel bottom tires, waveguides, heat pipes/sheets, conductive devices, etc.

Beryllium Copper C17200 has the characteristics of high strength, elasticity, hardness, corrosion resistance, high and low temperature resistance, no magnetism, and no sparks when impacted. Therefore, it can be processed into complex shapes by various molding methods. Mainly used in various springs, metal hoses, clips, and gaskets, and also used in aerospace navigation instruments.

CuZn15 brass has good mechanical properties and corrosion resistance, excellent cold workability, and good hot formability. CuZn15 copper is widely used in architectural decoration, corrugated pipes, serpentine pipes, water pipes, condenser and heat exchanger pipes, cooling equipment parts industries, etc.

Copper C11000 has high electrical conductivity, thermal conductivity, good corrosion resistance, and processing performance, and can be welded and brazed. C11000 is mainly used to make electrical, thermal, and corrosion-resistant components, such as wires and cables, conductive screws, housings, various conduits, and aerospace industry parts.

CuZn40 (H62) brass has high strength, good thermoplasticity, easy welding, good corrosion resistance, and easy dezincification and stress cracking in some cases. It is used in various pins, nuts, washers, stilling pipes, and radiators, parts for the sugar industry, the shipbuilding industry, the paper industry, etc.

Brass C35300 has the characteristics of hot forging and easy cutting. With its excellent machinability and high scrap return value, Brass C35300 is often used in parts with knurling or threads, moving parts subject to friction, and high-precision parts such as air conditioning valves.

In addition to brass machining services offered by china brass machining suppliers, we also offer aluminum machining services for lightweight and corrosion-resistant applications, and titanium machining for high-strength aerospace and medical components.

If you have high requirements for the physical properties of your product materials, copper and brass will be your good choice—ideal for china brass machining applications. Copper is one of the most machinable materials, and its acceptable price and good performance make it preferred by engineers.

CNC brass and copper parts are generally suitable for:

Fitting

Gears

Bearings

Turbine blades

Motors

Valve components

Fasteners

Pump components

Flanges

Not limited

Explore more of our CNC machining capabilities or go back to our homepage for a full list of materials, services, and industry applications. Get an instant quote for your custom brass CNC parts — upload your drawing today!

With the development of brass machining industrialization and regeneration technology, brass and copper machining production has developed in the direction of mechanization, continuity and automation. Specialized regeneration and production lines of important recycled brass varieties such as home appliances, electronic components and heat exchangers have appeared in foreign developed countries, and with economic development, copper and brass machining will appear as an important industry in the industrial system.

Our brass CNC machining services are widely used in electronic housings, medical fittings, and sensor connectors. Learn more about our solutions for the electronics industry and medical device manufacturing.

Get in touch with us

We will contact you within 24 hours

We are committed to providing rapid prototyping, CNC machining, Swiss machining, plastic injection molding, gear machining services. Contact us to get more info!